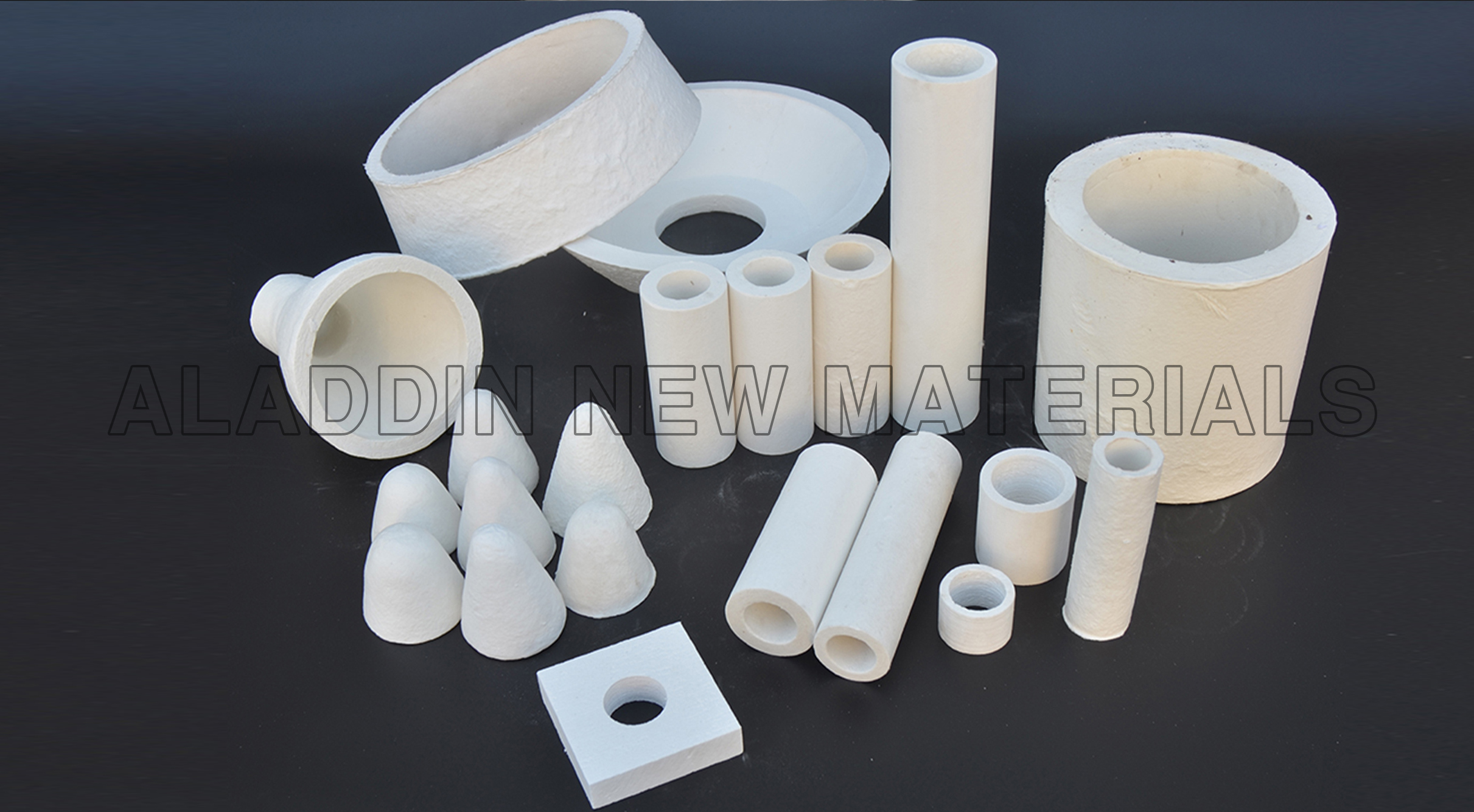

01 Introduction to Aladdin Vacuum-Formed Fiber Products

Aladdin vacuum-formed fiber products use high-quality ceramic fiber cotton as raw material and are manufactured using a vacuum forming process. These products are custom-shaped products required for specific production processes in certain industrial sectors. Each product requires a dedicated mold based on its shape and size, aiming to create rigid, self-supporting custom-shaped products with superior high-temperature performance. They are easy to cut or machine. During use, the products exhibit good wear and peel resistance and are not wetted by most molten metals.

02 Product Features

* Can be used directly in contact with flames for hot surfaces;

* High compressive strength and long service life;

* Vacuum-formed custom-shaped products, specially designed for fire-resistant insulation of specific parts of certain thermal equipment, with precise dimensions;

* Low shrinkage within the applicable temperature range, while maintaining its high insulation, lightweight, and impact resistance;

* Unburned material is easily cut or processed;

* Rigid material, high strength, tough texture, and strong wind erosion resistance;

* Low heat storage and minimal heat loss, providing excellent fire-resistant insulation;

* Excellent workability; good thermal shock resistance; significant sound absorption.

03 Typical Applications

a. Industrial kiln observation holes and thermometer insertion holes;

b. Industrial kiln burners and furnace doors; liquid collection tanks and flow channels in the aluminum industry;

c. Thermal radiation insulation for civil and industrial heating devices;

d. Non-ferrous metal melting channels, channel liners, and casting caps;

e. Electromechanical equipment connection gaskets.