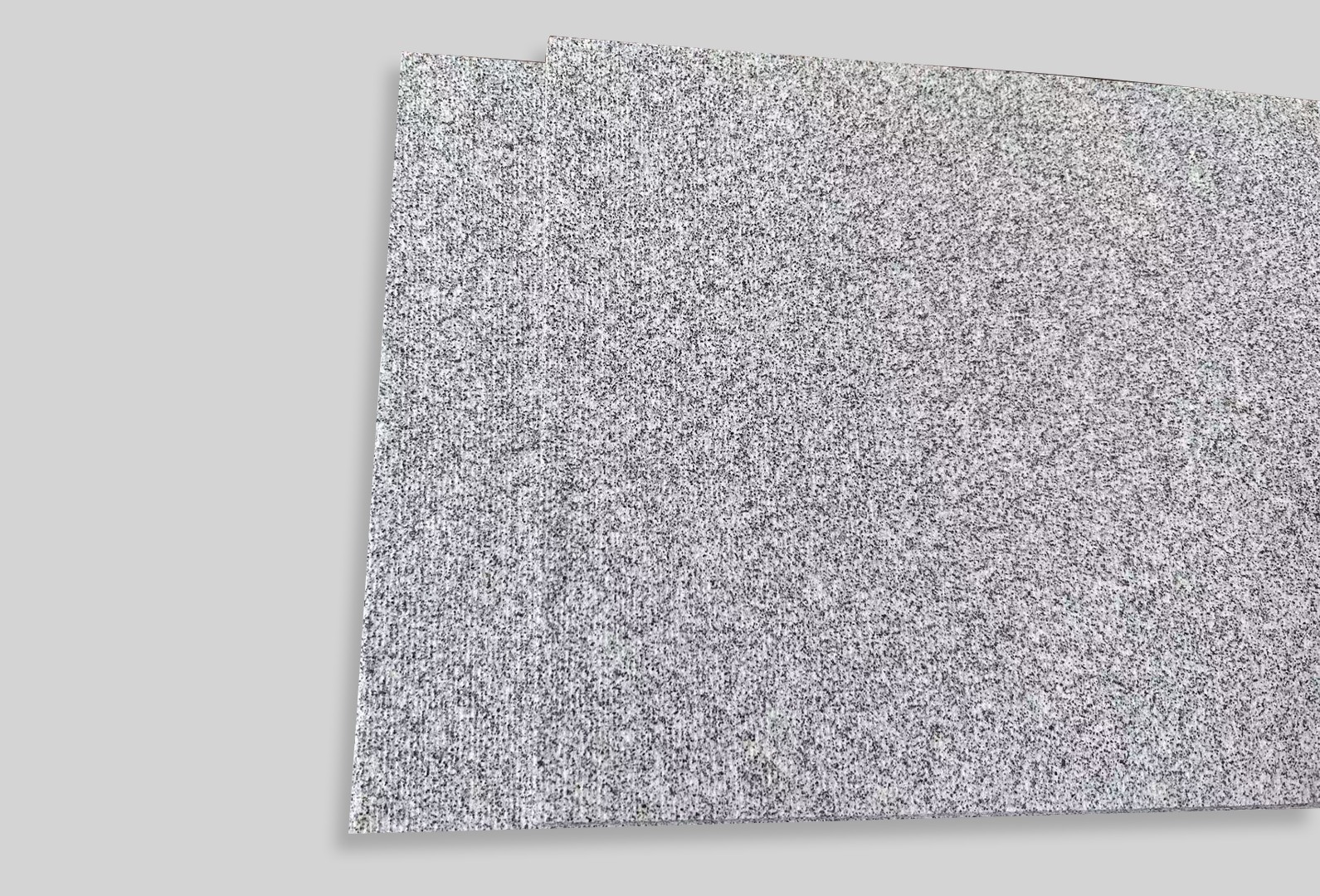

Expandable Graphite Ceramic Fiber Paper is a new type of high-performance composite material. It is manufactured using a wet-laid papermaking process from expandable graphite, ceramic fibers, and a small amount of inorganic binder. It ingeniously combines the excellent high-temperature resistance, thermal insulation, and expansion sealing properties of expandable graphite with the high strength, thermal shock resistance, and insulating properties of ceramic fibers, resulting in a unique and high-performing flexible sheet material.

It is as flexible as "paper" at room temperature, allowing for cutting.Under high temperatures, it acts like a "shield," rapidly expanding to form a sturdy, heat-insulating sealing layer.

When the temperature reaches the initial expansion temperature of the expandable graphite (typically above 150℃), the intercalation compounds decompose, causing the graphite to expand instantaneously along its axis (expansion ratio can reach several tens to hundreds of times).

The expanded graphite forms a vermicular, porous, and fluffy carbon layer that effectively fills gaps, voids, and irregular surfaces, creating a dense and stable barrier against gases and flames.

Excellent Thermal Insulation and Fireproof Performance

The microporous carbon layer formed after expansion is an excellent thermal insulator with very low thermal conductivity.

The ceramic fibers themselves are top-grade refractory materials, with long-term use temperatures reaching above 1000℃, or even higher (depending on the ceramic fiber type).

The combination of both enables the product to effectively block heat transfer at high temperatures, protecting structures and equipment on the non-fire side.

Outstanding Flexibility, Workability, and Mechanical Strength

At room temperature, it possesses paper-like flexibility, allowing it to be easily curled, folded, and wrapped around pipes, valves, and equipment with complex shapes.

The incorporation of ceramic fibers significantly mitigates potential shrinkage and powdering issues associated with pure graphite materials under repeated thermal cycling.

The product can withstand severe temperature fluctuations without cracking or spalling, ensuring a longer service life.

The expanded graphite layer exhibits good resistance to most acids, alkalis, and organic solvents.

Under inert atmospheres or short-term high temperatures, the graphite carbon layer possesses oxidation resistance. Some grades undergo anti-oxidation treatment to extend service life in high-temperature, oxygen-containing environments.

The main components are graphite and ceramic fibers, both inorganic non-metallic materials. It is asbestos-free and does not release toxic fumes at high temperatures, complying with environmental requirements.

Industrial Fire Protection and Sealing.

New Energy Vehicle and Energy Storage Safety

Power Battery Pack Thermal Protection: Wrapped between battery modules or within the entire battery pack, it rapidly expands during a cell thermal runaway event, isolating high temperature and flames to prevent propagation throughout the pack. It is a key material for enhancing battery system safety.

Energy Storage System (ESS) Fire Protection: Used for fire isolation within battery cabinets and for sealing pressure relief channels.

| Product Name | Expandable Graphite Ceramic Fiber Paper |

| Temperature(℃) | 1260 |

| Density(Kg/m³) | 220-250 |

| Expanslvity(%) | 500-600 |

| Specification(mm) Special specifications can be customized according to customer requirements | 60.000x610/1220x1 30.000x610/1220x2 20.000x610/1220x3 15.000x610/1220x4 12.000x610/1220x5 10.000x610/1220x6 |