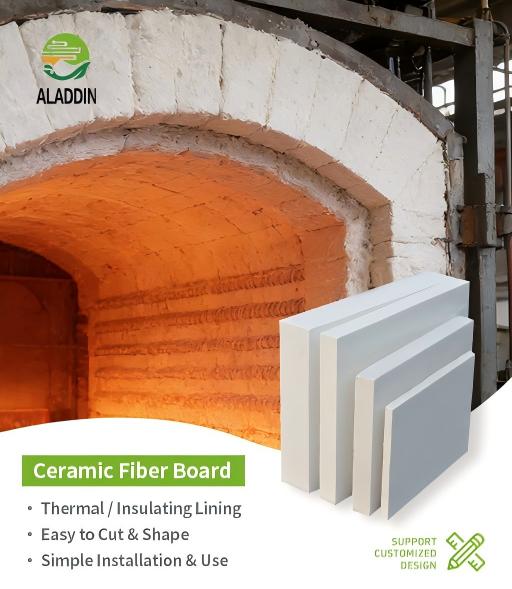

Ten Outstanding Advantages of Ceramic Fiberboard as a Modern Kiln Liner

As industrial kilns and thermal equipment continue to evolve towards higher efficiency, energy conservation, and intelligence, the choice of lining materials directly determines the performance and economic benefits of the equipment. Ceramic fiberboard, as a revolutionary refractory and heat-insulating material, is gradually replacing traditional refractory bricks and castables, becoming the preferred choice for kiln lining design due to its comprehensive performance advantages. Its core value can be summarized in the following ten aspects:

01 Extremely Lightweight, Reduced Structural Load

Ceramic fiberboard has an extremely low bulk density, only 1/5 to 1/7 that of traditional refractory bricks and about 1/6 that of lightweight castables. This characteristic significantly reduces the load on the kiln's steel structure, lowers the main construction cost, and provides a solid foundation for the large-scale and lightweight design of equipment.

02 Excellent Thermal Insulation, Significant Energy Saving

Thanks to its unique porous fiber structure,ceramic fiberboard has an extremely low thermal conductivity, and its thermal insulation performance at room temperature is more than three times that of lightweight insulating bricks. More importantly, within a temperature range exceeding its classification temperature (e.g., 1260℃, 1400℃), its thermal conductivity increases slowly with temperature, effectively blocking heat flow and reducing furnace heat loss, resulting in exceptionally high energy savings.

03. Durable Temperature Resistance, Stable and Reliable

Ceramic fiberboard is available in multiple temperature grades depending on the raw materials, with a long-term operating range covering 600℃ to 1400℃ and even higher. Even at extreme temperatures, it maintains structural integrity, without pulverizing or melting, ensuring the long-term safe operation of the furnace lining.

04. Low Heat Capacity, Rapid Response

Its lightweight and low specific heat capacity (approximately 1/10 that of lightweight castables) significantly reduces the heat storage capacity of the furnace. This brings two core benefits: firstly, a sharp reduction in energy consumption during furnace start-up and shutdown, significantly saving operating costs; and secondly, faster furnace temperature rise and fall, greatly improving the production efficiency and flexibility of intermittent kilns.

05. Excellent Thermal Shock Resistance, Extended Lifespan

The material's interior is filled with flexible fibers and uniform pores, perfectly absorbing and buffering thermal stress caused by rapid temperature changes. Whether under rapid heating or forced cooling, ceramic fiberboard furnace linings are not prone to cracking or peeling, fundamentally overcoming the shortcomings of traditional refractory materials susceptible to thermal shock damage, thus significantly extending maintenance cycles and overall service life.

06. Convenient Construction, Immediate Use

The panels are precisely sized and have a smooth surface, allowing for easy on-site processing such as cutting and drilling. Installation is simple and flexible, and can be completed quickly using various methods such as bonding and anchoring. After construction, there is no need for a lengthy and complex furnace drying process; production can begin immediately, greatly shortening project timelines and commissioning time.

07. Excellent Chemical Stability and Strong Environmental Adaptability

Except for a few media such as hydrofluoric acid, strong alkalis, and phosphoric acid, ceramic fiberboard exhibits excellent resistance to most acids, alkalis, water vapor, oils, and molten metals (such as aluminum and copper), making it suitable for various complex industrial furnace atmospheres.

08. Noise Reduction and Environmental Improvement

Its porous fiber structure also makes it a highly efficient sound-absorbing material. For high-frequency noise below 1000 Hz and sound waves below 300 Hz, its sound insulation performance is superior to commonly used sound insulation materials, effectively reducing noise pollution generated by kiln operation and improving the working environment.

09. High Thermal Sensitivity and Precise Temperature Control

The low heat capacity characteristic makes the furnace lining extremely sensitive to temperature changes. This helps improve the accuracy and response speed of the temperature control system, providing ideal conditions for achieving precise temperature control and fully automated operation of the kiln.

10. Wide Application and Economic Efficiency

From low-temperature heat treatment furnaces to high-temperature industrial kilns, from direct contact with the hot surface to backing insulation, ceramic fiberboard can be applied in various scenarios. Combining its multiple advantages such as energy saving, extended lifespan, and reduced construction and maintenance costs, its comprehensive economic benefits throughout its entire life cycle far exceed those of traditional materials, making it a core guarantee for achieving the goals of "high quality, high output, low consumption, and long lifespan" for kilns.

Ceramic fiberboard, with its lightweight, highly efficient thermal insulation, and rapid response properties, combined with excellent durability and ease of installation, ultimately translates into tangible energy savings, increased efficiency, and reduced costs for users. Choosing ceramic fiberboard means choosing higher operating efficiency, lower energy costs, and more reliable future production assurance.