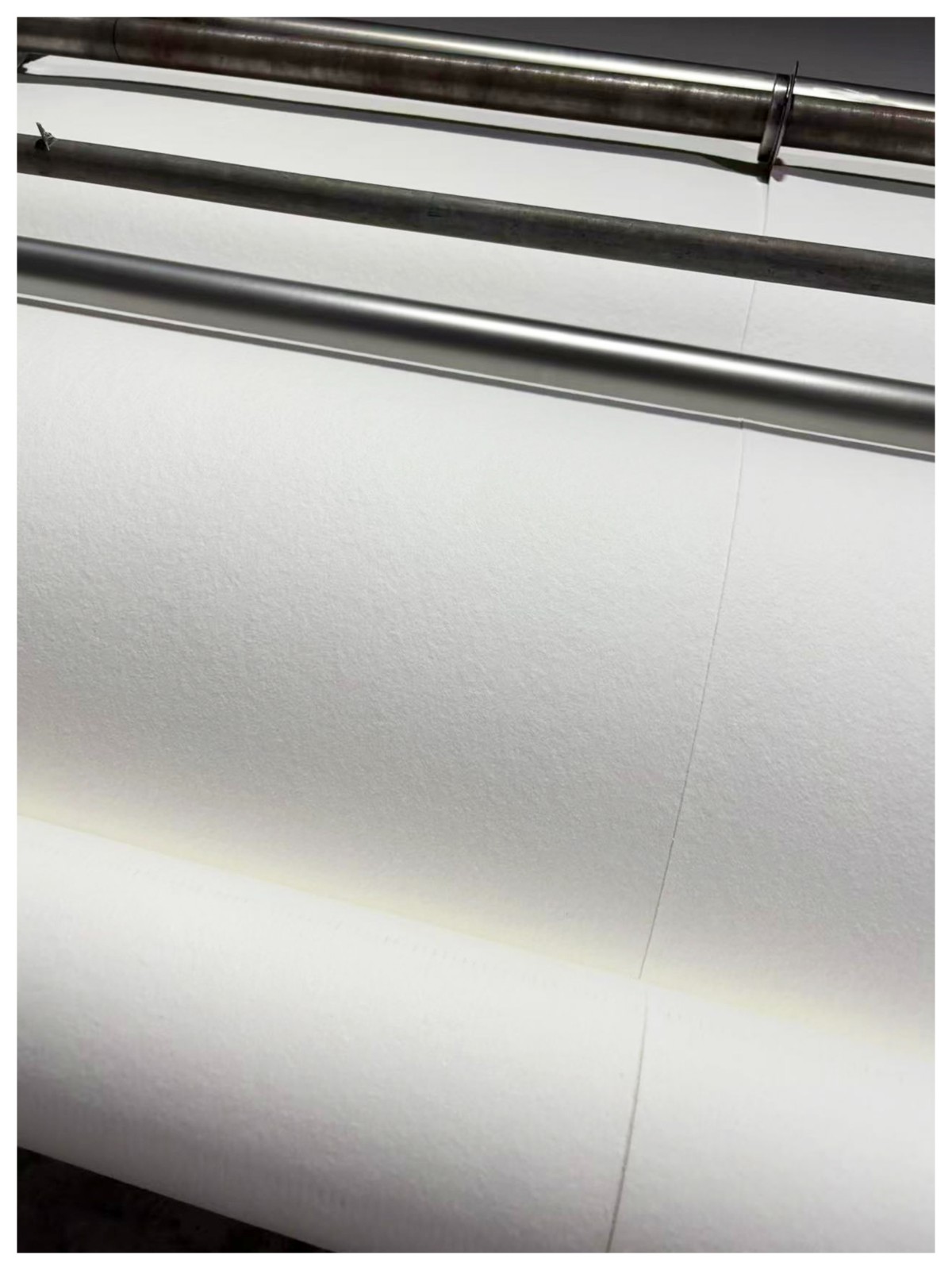

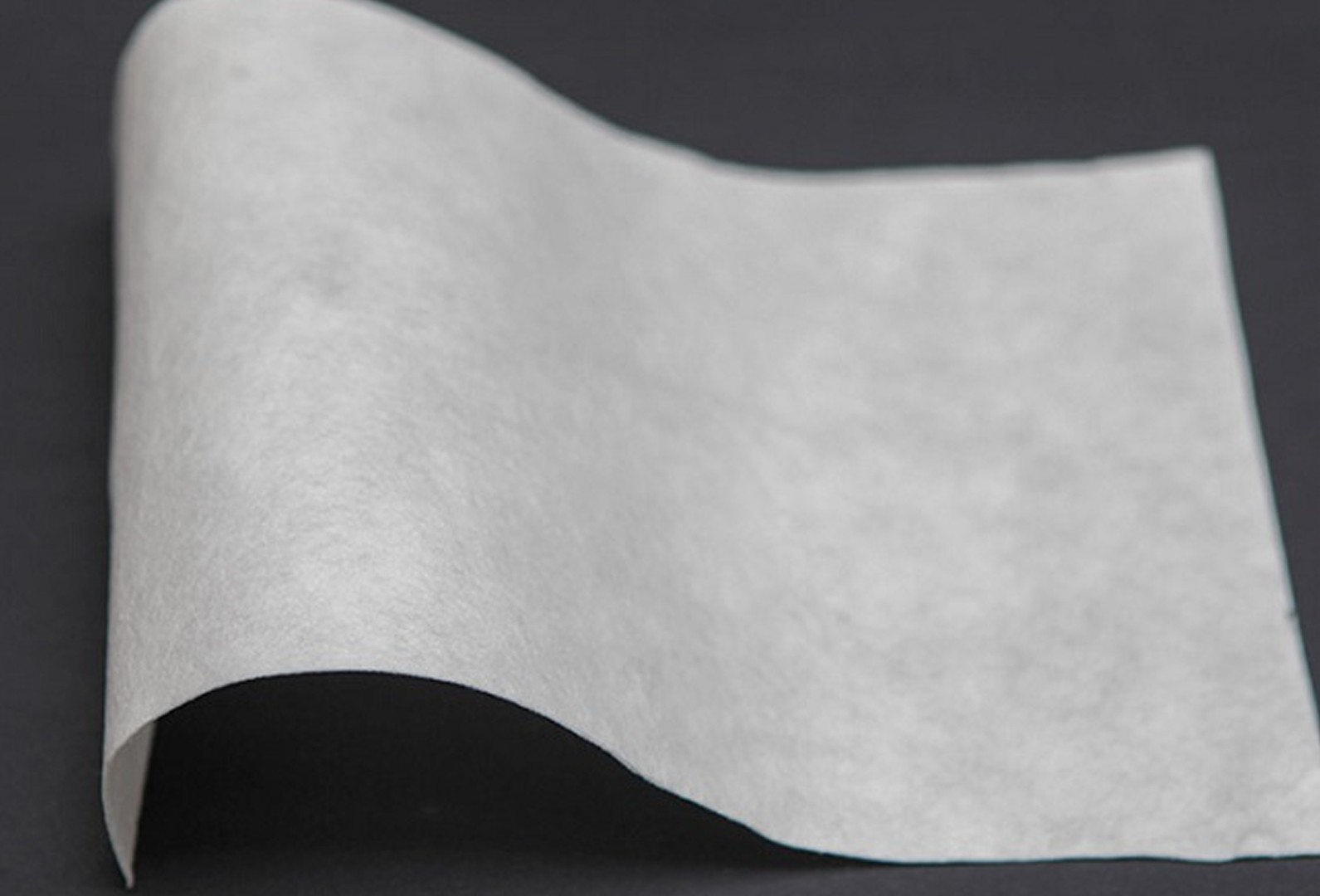

1600 Alumina Fiber Paper is an advanced refractory and thermal insulation material made from high-purity polycrystalline alumina fibers. Utilizing a process similar to papermaking, extremely fine, amorphous polycrystalline alumina fibers are formed into a uniform, flexible, paper-like material.

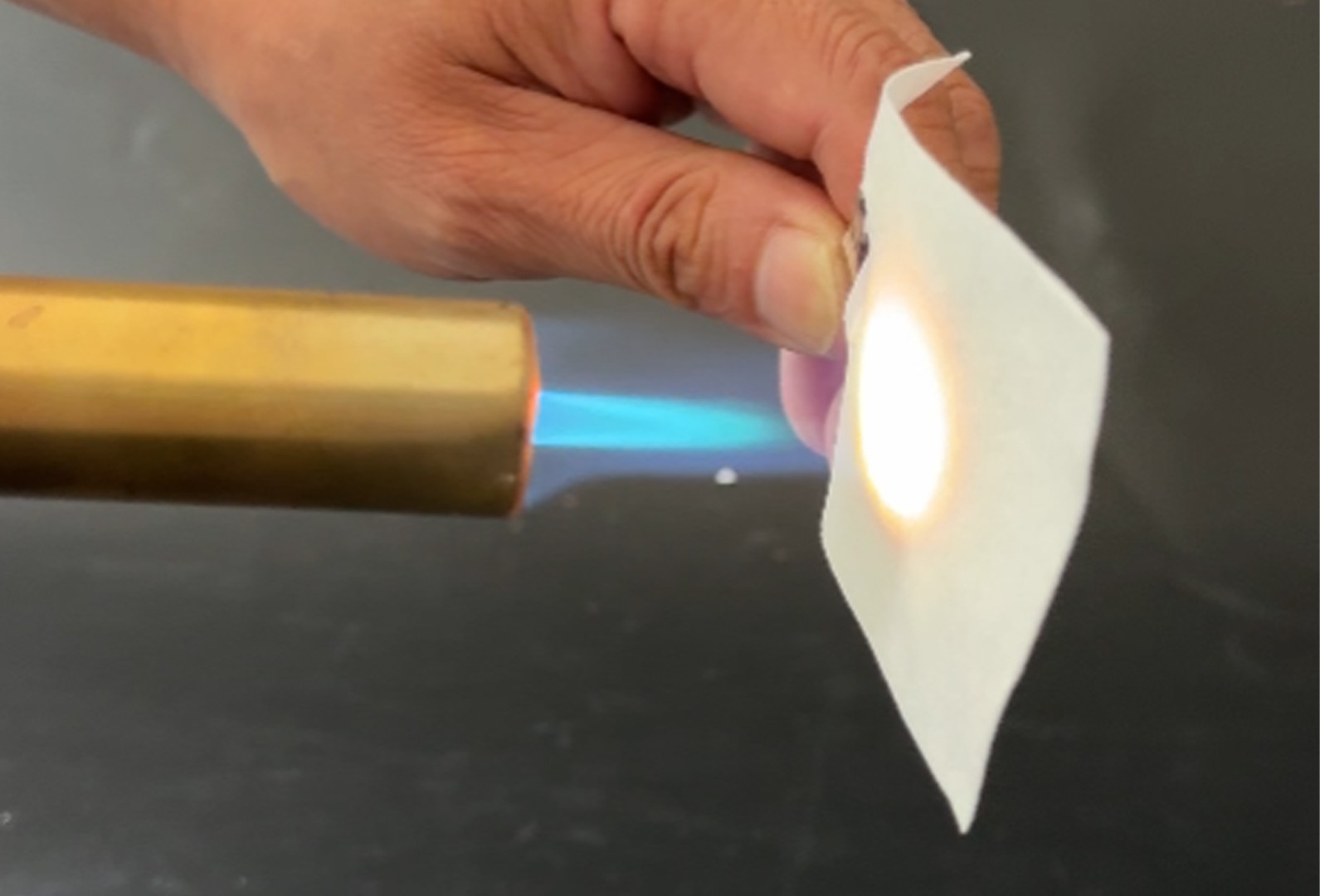

High Melting Point: Exceeds 1840℃.

Low Thermal Conductivity: Excellent insulating properties.

No Glass Phase: Polycrystalline alumina fibers exhibit no crystalline phase transitions during heating and cooling, ensuring dimensional stability and no shrinkage.

Excellent Thermal Shock Resistance: The fibrous structure provides outstanding flexibility, enabling it to withstand severe thermal cycling and mechanical vibration without cracking or powdering. It is flexible and can be easily cut.

Good Chemical Compatibility: Demonstrates excellent resistance to most chemicals and corrosive environments (such as hydrogen, carbon monoxide, vacuum), and does not wet with molten metals (e.g., aluminum, copper).

Uniform Texture: Even fiber distribution ensures consistent thermal insulation performance.

Compliant with EU ROHS Directive.

High-Temperature Industrial Furnaces & Kilns

Aerospace & Military Industry

Crystal Growth & Semiconductor Industry

Heat Treatment & Brazing

Laboratory & Scientific Research Equipment

High-Temperature Filtration, Carrier for High-Temperature Catalysts, etc

| Category | ALDS003 | ALDS006 | ALDS008 | ALDS010 | ALDS020 | ALDS030 | ALDS040 | ALDS050 |

| Insulation performance 1000V DC(MΩ) | ≥500 | |||||||

| Fiber diameter(μm) | 5.5-7.5 | |||||||

| Tensile strength (kPa) | ≥200 | |||||||

| Flame retardant | Meet | |||||||

| Thermal conductivity( W/m·K) | ≤ 0.04 | |||||||

| Chemical composition(%) | Al2O3≥ 99.2 | |||||||

| Thickness(mm) | 0.30 | 0.60 | 0.80 | 1.00 | 2.00 | 3.00 | 4.00 | 5.00 |

| Thickness range(mm) | 0.25-0.35 | 0.50-0.70 | 0.70-0.90 | 0.90-1.10 | 1.80-2.20 | 2.70-3.30 | 3.60-4.40 | 4.50-5.50 |

| Areal density(g/㎡) | 20 | 60 | 80 | 100 | 250 | 400 | 550 | 700 |

| Areal density range(g/㎡) | 15-25 | 50-70 | 70-90 | 90-110 | 225-275 | 360-440 | 495-605 | 630-770 |